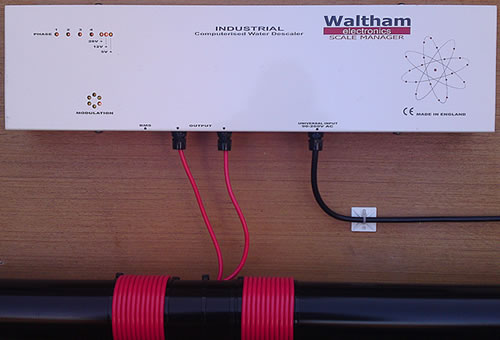

What is Scale Manager? SCALE MANAGER is the ultimate water descaler

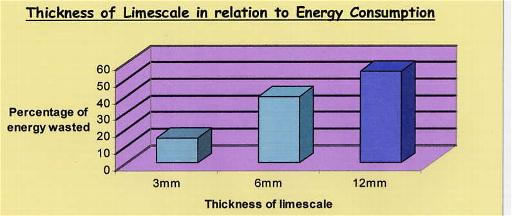

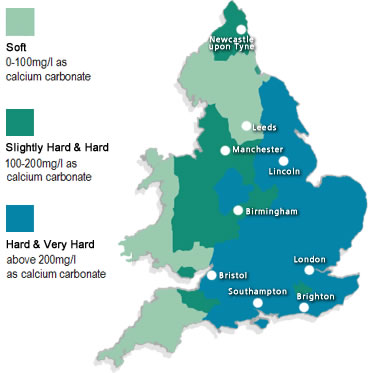

WATER is one of the worlds most precious natural resources. However, hard water in industry causes wasted energy and early replacement of water fed appliances

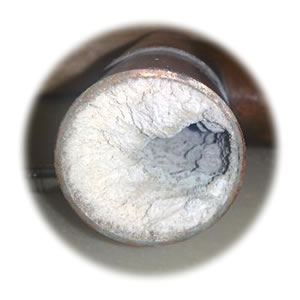

SCALE MANAGER is the ultimate water descaler providing maintenance free hard water solutions and limescale prevention; Scale Manager will remove existing limescale without the need for chemicals, salts, or alteration to plumbing and provide limescale prevention in the future. The Scale Manager effect does not alter the chemical composition, but achieves all of the advantages of a limescale free system.

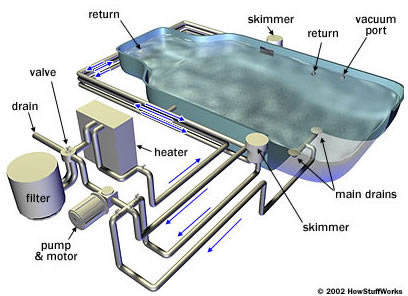

As the treated water flows through your system the water now being more soluble will reverse the limescale forming process, disintegrating the build-up already present, and offer future limescale prevention.

We can reduce your industrial hard water issues without any interruption to your business or production

Why use Scale Manager?

Our electronic descalers have the latest digital technology and robust powder coated metal enclosures, ensuring sustainability for today’s environment.

- Electronic units are covered with a 5 year component warranty

- Expected life span of 15 years plus

- Very low energy consumption

- No maintenance required

- No Interruption to services or production

- BMS connection if required

- Can be installed over lagging

- More than one pipe can be treated with one electronic unit

- Can be used with any flow rate, pipe size or material

- Reduces bacteria levels